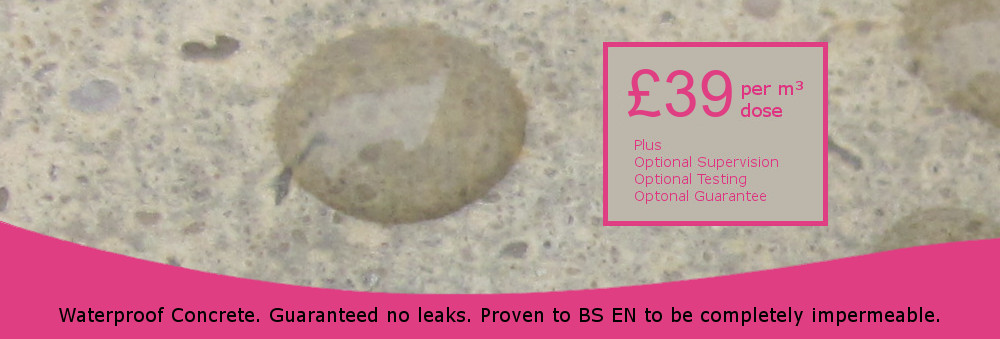

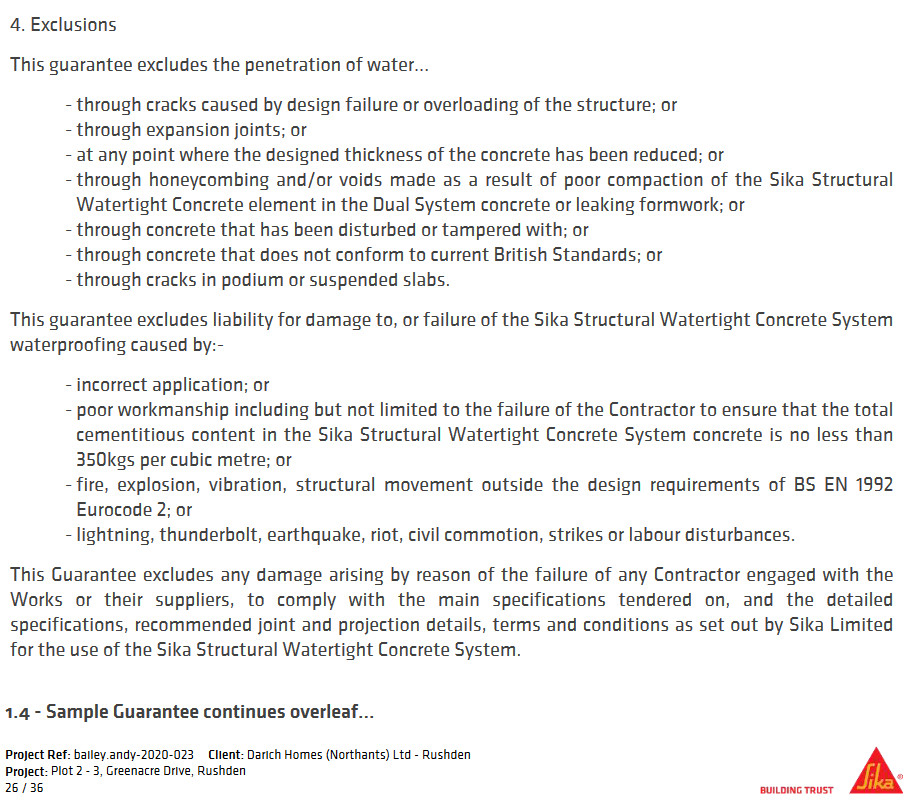

Somewhere in the world I concede this could be true. But all I see from them in the UK is basically mutton dressed as lamb. Crap dressed up to look nice. Just like Caltite, it is a whole system that they claim 'provides waterproofing'. But, just like Caltite, their system includes a waterproof concrete mix that only needs a powerful enough plasticiser to place and compact it easily enough and the system works. It would work without all the additional products you seem to need to buy to get their warranty, which as we will see below, seems to provide a warranty for nothing except the good quality concrete. For several years I supplied my own powder to a readymix company south of London. But a year ago I decided to de-register for VAT and I did not want a wholesale customer any more, They tried Sika first because it was cheapest. They didn't like it. Not as good as the powder I had supplied. As at August 2022 they are trying some others. They asked me more than once to reconsider selling to them again. Another customer of mine first got Sika to quote but he chose me. You can open the Standard Sika Specification using the link. You have to get all the way to page 26 before you find they exclude poor workmanship and voids. Voids obviously includes the holes carpenters deliberately leave through a wall as well as voids due to poor compaction, which Sika call honeycombing. Sika specification - Standard (1).pdf. These are the exclusions, from page 26 of the document linked to just above. Sika boast, above, "keeps water out" But keeping water out is not guaranteed by Sika because the first exclusion is "This guarantee excludes the penetration of water"

What Sika mean is water won't penetrate the correct mix of concrete. They have no evidence and they make no suggestion that their product reduces permeability. The only worthwhile ingredient is the same as mine and everyone else's. A plasticiser to enable a dry mix of concrete to be pumped and compacted. And the evidence from the readymix producer I stopped supplying is that Sika's is not that good. Perhaps Sika's product is just cheap rubbish. During 2019, I was paid to observe and comment on a concrete pour where Sika was used. Nothing else. Just observe and report. I did none of the work. But I did spot some steel tied wrongly, which building control earlier the same day had missed, and that would have voided the Sika Guarantee, "failure ... . to comply with the main specifications", had I not got it put right. I picked up many failings of workmanship and supply of the Sika treated concrete. Here I bring your attention to the difficulty fixing a Sika hydrophylic strip, supplied curled up in a box, to a straight piece of concrete. Note in the exclusions: "through expansion joints".

The strip tends to pull itself off the hardened concrete as tries to curl up again, it will no longer be continuous in the joint because fresh concrete will get behind the strip. It is a virtually impossible task to do properly. a bad product for that reason. And any failure due to it being a bad product is excluded from the warranty. Because expansion joints are excluded. Note, also, that the exclusions refer to "the failure of the Contractor to ensure that the total cementitious content in the Sika Structural Waterproof Concrete System concrete is no less than 350kgs per cubic metre" Contractors are blokes who work physically very hard and get dirty most days because they did not get the education to get themselves a less back-breaking job. Who explains minimum cement content to someone not that fond of reading? Who trains the bloke down the hole spreading and vibrating the concrete that up the top, behind the concrete pump truck, the concrete delivery driver wants a signature? The pump operator usually signs tickets, but since Covid most concrete does not come with a ticket and no signature is sought any more. The delivery driver just drives off. The true course of events is more likely to be that the Contractor phones up the concrete supplier and tells them Sika has been specified. The Contractor expects, and should be allowed to expect, that the professionals supplying the chemical and the professional designing and batching the concrete do their jobs properly. Or else the professionals should be responsible. Some might think Sika are a bit too clever and promote a warranty they never have to pay out on. Here is the second Sika BBA certificate I studied after I first wrote this page " A combined water-resisting and super plasticising mixture." Here is the latest, the third I have seen, certificate that I haven't gone through carefully yet. It makes the same claim: 'water resisting and high range water reducing superplasticising admixture'. The second certificate includes 'crystalline' which means it includes cement. The third certificate does not mention 'crystalline' in its first paragraph, but if it still contains some cement then that explains the extra water resistance. The second certificate is in a different place on the internet to the first certificate I studied years ago. There might be some differences. I note on this second certificate

It doesn't really seem to be any different to Xypex, Kryton or Triton in that it is adding a little bit more cement, the necessary plasticiser (though my wholesale customer would say it is not as good as mine), some sand to help break open the paper sack and some paper. Each sack weighs 1.75kgs so the cement content must be less than that. Adding another kg of cement to the 350kgs specified makes no real difference. But even a slight difference makes any claim that it reduces permeability, increases strength and reduces the water cement ratio true. But I doubt by enough for the project client or the contractor to tell the difference or derive any meaningful benefit, for what is a lot of money by the time the contractor pays the invoice.

The slump in the control and Sika concretes tested for certification was quickly much less than 100mm to 150mm. Did they test different concrete?

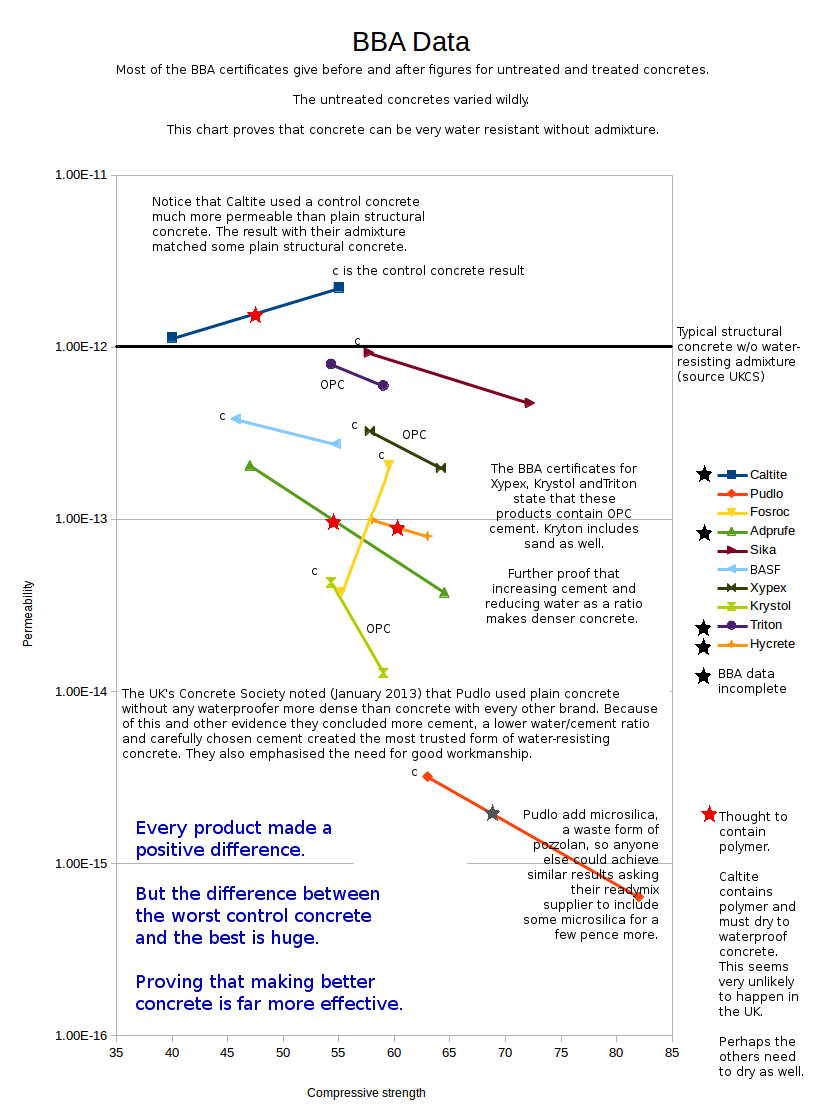

A customer of mine got Sika to quote but he used me. You can open the Standard Sika Specification using the link. You have to get all the way to page 26 before you find they exclude poor workmanship and voids. Voids obviously includes the holes carpenters deliberately leave through a wall as well as voids due to poor compaction, which Sika call honeycombing. Sika specification - Standard (1).pdf. Over the years we have had a few phone calls from people who saw our web site but decided, or their specifier decided, to go with a famous brand or a BBA certificate. These people wanted to tell us how they regretted their choice and wished they had used us. Some were incandescent with anger at how different their experience had been compared to what they expected. We mention it here because they all seem to have involved Sika. See the chart below. BBA certificates have figures for water permeability. The Concrete Society had the idea of plotting them all on a chart. We have done that as well. But we have also included some best guesses. For instance, only the Caltite certificate has no figures for compressive strength. Some of the control concretes were better than concretes with admixture in them. The Sika is in a very poor position.

|