|

|

Pudlo looked into.

Pudlo was fast becoming market leader following years of presentations to architects and chartered engineers.

(But it went into administration and got sold twice by 11 July 2025. I don't know what changes the new owners may make in future.)

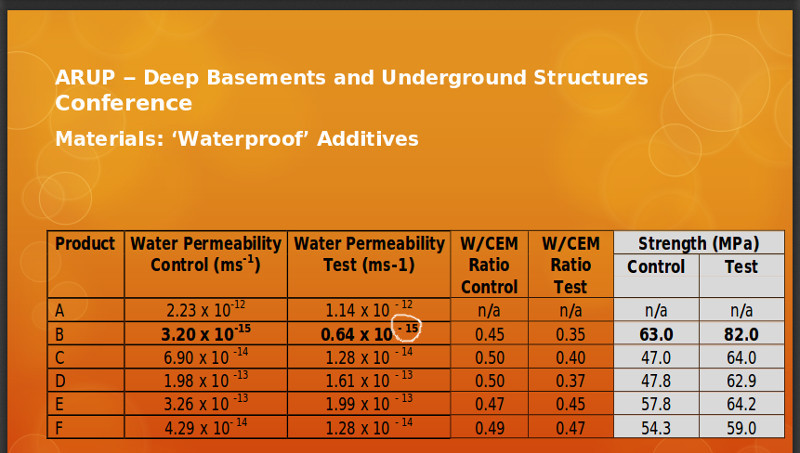

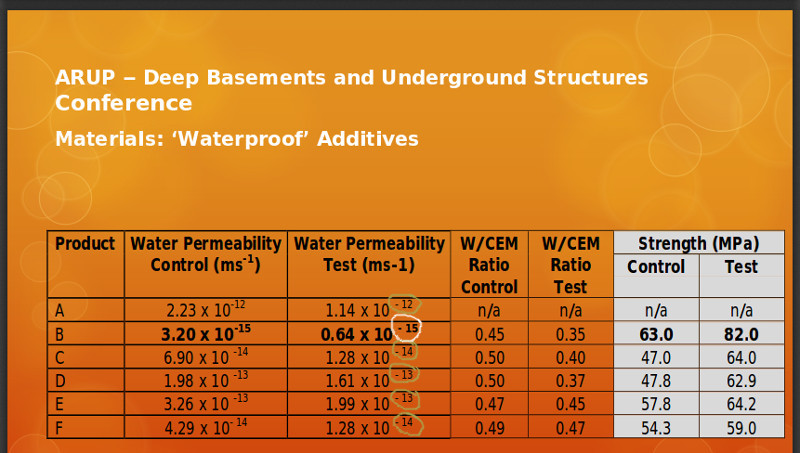

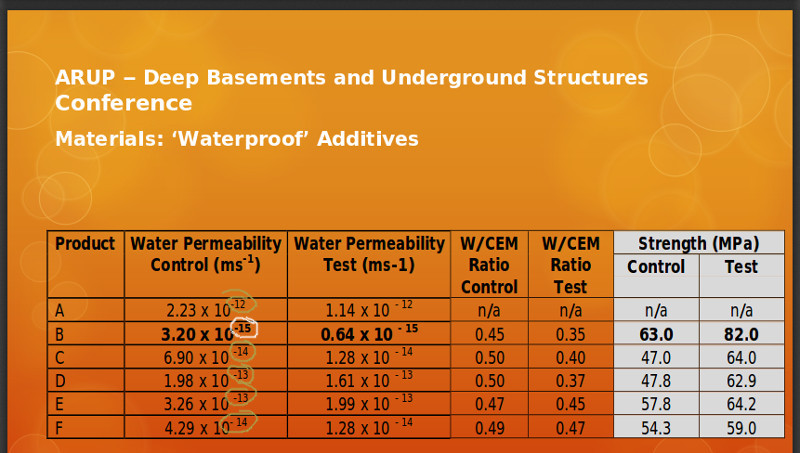

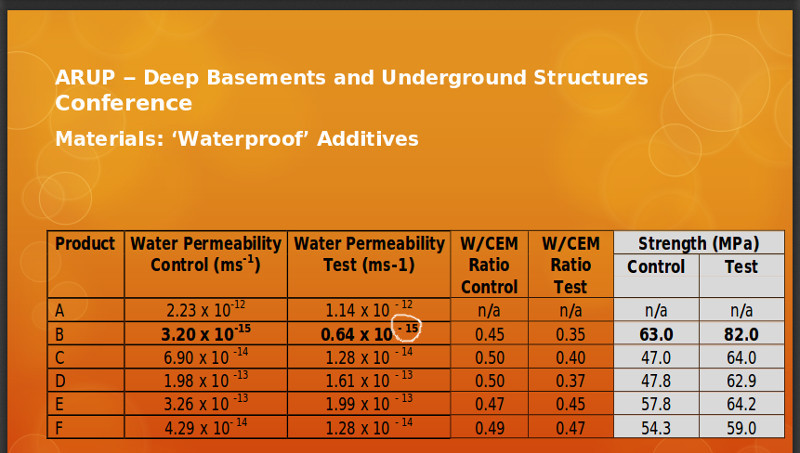

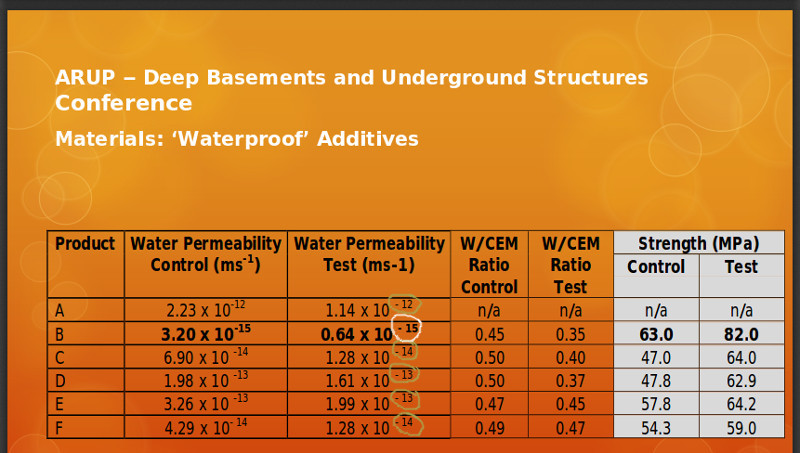

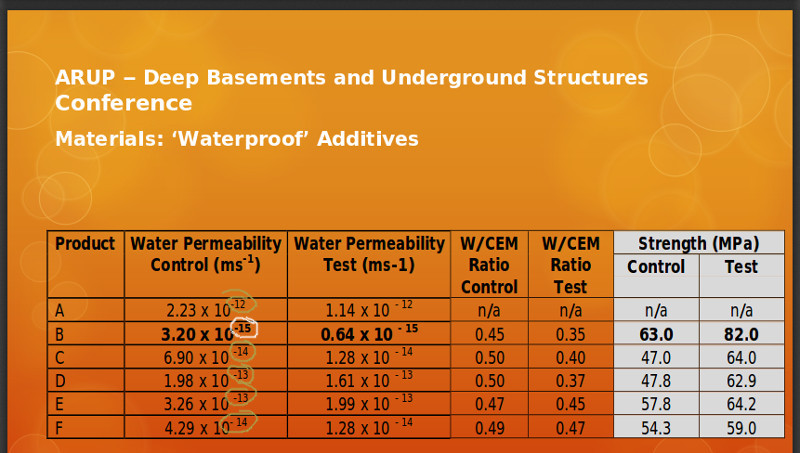

They always showed the figures on the slide below. It would seem to prove that they had the most water resistant result of all the tests carried out by BBA on all the water resisting admixtures.

But, actually, it just shows that they made a second batch of concrete with less water - far too little water for that concrete to be used on site - but since they managed to compact it in the lab, obviously it made denser concrete.

As the causes and the blame for the Grenfell Tower disaster unfold, one accusation out there is that BBA and BRE collude, for money, to help products (such as the Reynobond cladding and Celotex insulation) get a satisfactory test result by allowing them to test, retest and retest again. Some think that the Celotex failed more than once before enough intumescent protection was put around it so it could eventually survive.

Sadly the contractors fitting it don't seem to have put as much fire protection around it on the tower. Perhaps they weren't told to.

Did Pudlo simply pay BBA a little more money to find a way for their product - that actually does precious little - to appear to be so much better that it is becoming market leader?

|

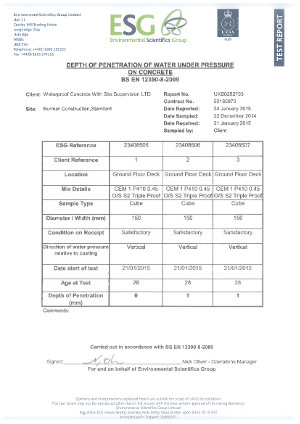

I was sent this email in 2014.

|

|

|

|

|

Please note. The author acknowledges all the trademarks it mentions on this site.

|

|

|

|

|

"

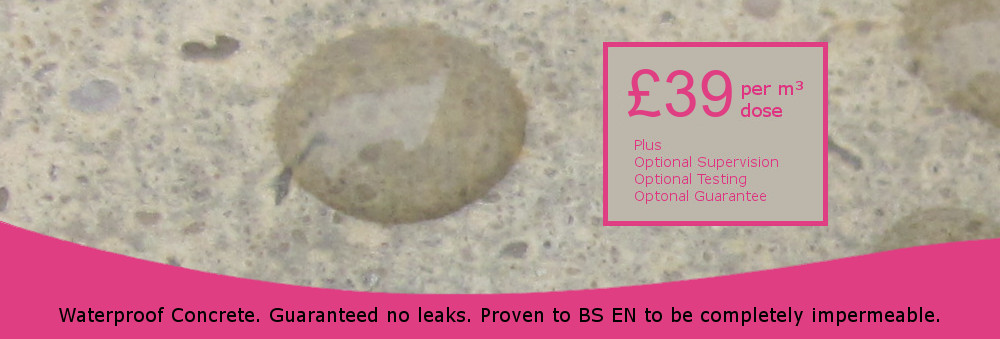

Interesting conversation with Pudlo the other day. Their banner header says "Waterproof Concrete - Watertight Guarantee" and though there were many downloadable docs on the website there was no copy of aforementioned "Watertight Guarantee". So called up and asked where it was and to get a copy. Told it wasn't on website and she couldn't give me a copy but I could speak to one of their regional salespeople. Did this and it was like pulling teeth to find out that:

a) If you have under 100 cu.metres of concrete it doesn't apply and there is no guarantee at all.

b) If over 100 and less than 300 cu.m. then for £1200 they will give the "Watertight Guarantee"

c) If over 300 cu.m it is free.

I was told that the amount of warranty is not fixed but is a percentage of the remedial costs to fix the problem up to 100%. "That's very good", I said "but is there a limit to the amount perhaps related to the spend on the materials?"

"Well yes there is".

"So if your product fails you repay up to the amount of the spend"

"Yes that's right"

"What about the £1200 we would also have paid to your company? Do we get that back too"

"No of course not. That is for the work we put in to make sure it all goes right!

"

I can add three more points to this tale.

-

We understand that no guarantee is issued until Pudlo have inspected and can see no leaks. So if the assertion above "the work we put in to make sure it all goes right!" is a true quote it cannot be a true fact since the contractor has to pay for all the known leaks to be repaired before any guarantee is issued.

-

If a contractor asks for the guarantee to be insurance backed we have been told he is asked to pay extra for the cost of his insurance. So if the insurance is mis-sold (where no claim could ever be possible) there is a clear contract to prove it was sold.

But note this from the tale above "So if your product fails you repay up to the amount of the spend". As we keep pointing out, all the admixture suppliers exceed C35A with the base concrete that their plasticiser or cement is added to, so the concrete cannot fail. Surely their concrete admixture cannot fail since it is unnecessary, and where any tapes or strips fail voids in the concrete will be obvious and the contractor will suffer the full cost of repair.

Aren't Pudlo selling specifiers an insured watertight concrete guarantee that guarantees nothing at all, is not always in place and is not insured unless extra is paid?

We have been told many times that Pudlo do CPDs at specifiers' offices and point out these numbers. This image is taken from their presentation available online. I have added the circles around the scientific notation.

This first number is the most impressive in the table.

The figure for the Pudlo-treated concrete is by far and away the best on the slide.

About 1,000 times better than the figure just above it (Caltite).

But they probably fail to point out that this figure was obtained using concrete with a slump of only 45mm - which would be absolutely useless on a construction site because it could not be pumped or compacted. Source the same as Pudlo's. Their BBA certificate.

The other figures are from BBA certificates as well.

What I imagine they don't point out so clearly is that the control concrete figure for Pudlo was also much better than all the other figures on the slide as well. They don't prove that they waterproof concrete any better than the others, they prove only that they started with a relatively waterproof concrete and the others didn't.

But I bet the impression they give, moving on quickly, is that Pudlo puts the rest in the shade.

The numbers are all from BBA certificates.

Lower down we reproduce these numbers on a chart. But what we want to draw your attention to early on is the reduction in water in the treated concrete compared to the plain concrete.

With massively reduced water, permeability was cut slightly but not prevented and compressive strength was a massive 82 MPa. Most aggregates are not capable of 82 MPa. They used something special, or unusual.

Getting fabulous results with less water is not remarkable. We had the same thing somewhat by mistake on a job in 2014. The concrete was very stiff and the workforce had a very tough time compacting it and getting a finish. But all credit to them, they did.

So at the end of this page we show you the similar effects we got on site with a similar water cement ratio. As luck would have it the 7 strong team were employees and had to work hard till the job was done. I don't think self employed would have persevered with such stiff concrete.

|

But we must question the figures for the same and usual reason, that the BBA tested concrete that would surely have to be rejected on site, or else have more water added?

The Pudlo BBA Certificate.

My comments

brochure 1954

We have been told that nowadays the CWP powder is microsilica (silica fume). 100 ago CWP used to be described as fatty acid, carbolic soap. So it has recently changed.

There is no doubt, microsilica and powerful plasticiser is a good combination. But just 8kgs in 2400kgs of concrete? That is enough plasticiser to increase the density of the concrete but surely not enough microsilica to be in every void throughout.

The customer is told to buy concrete with less cement and more water than the BBA tested.

|

|

These quotes are all from the Pudlo product certificate on the BBA web site

here.

But we have changed the order in which they appear.

This Agrément Certificate Product Sheet relates to Pudlo CWP (Cement Waterproofing Powder), a hydrophobic, pore-blocking admixture for use in concrete mixes or cementitious render to provide watertight concrete or render. The product is suitable for basements, roofs,

swimming pools, tunnels and culverts without the requirement for additional applied protection

28.1 This certificate:

Has to be read, considered and used as a whole document - it may be misleading and will be incomplete to be selective

1 Description

1.1 Pudlo CWP (Cement Waterproofing Powder) is a powder admixture which, when incorporated into concrete or render, enhances the water resistance and durability of the hardened product. The product does not contain Portland cement.

1.2 Pudlo Self-Compacting Admixture (SC) is a blend of Pudlo CWP and a superplasticising admixture, used to produce watertight flowing concrete. The self-compacting characteristic of the resultant concrete has not been assessed by the BBA and is outside the scope of this Certificate.

3.4 The product is classified as 'irritant'

3.5 When handling the product, the normal health and safety procedures associated with cementitious materials should be observed.

From

Table 1 Test mix details and properties of fresh wet concrete(1)

|

Component/Property (unit)

|

Control (plain) concrete

|

Pudlo CWP/Admix 500 concrete

|

|

Portland cement (BS12, Class 42.5N)

|

375

|

375

|

|

Slump (mm)

|

50

|

45

|

|

Water/cement ratio

|

0.45

|

0.35

|

|

Pudlo CWP (kg)

|

-

|

7.5

|

|

Admix (kg)

|

-

|

1.5

|

(1) The specific effect of the product on these properties for a particular mix and site conditions should be evaluated through site trial prior to use.

20 Mix design

20.2 The concrete must have a minimum cement or cementitious binder content of 350 kg/m

–3 and be batched with a maximum water/cement ratio of 0.4.

|

|

The concrete tested has very little water and only 45mm slump

YET WE ARE TOLD THAT PUDLO CONCRETE IS SELF COMPACTING BUT THAT FEATURE WAS OMITTED FROM THE BBA TEST SAMPLES. WHY? WOULD THE CONCRETE HAVE BEEN MUCH LESS WATER RESISTANT?

What has been hidden?

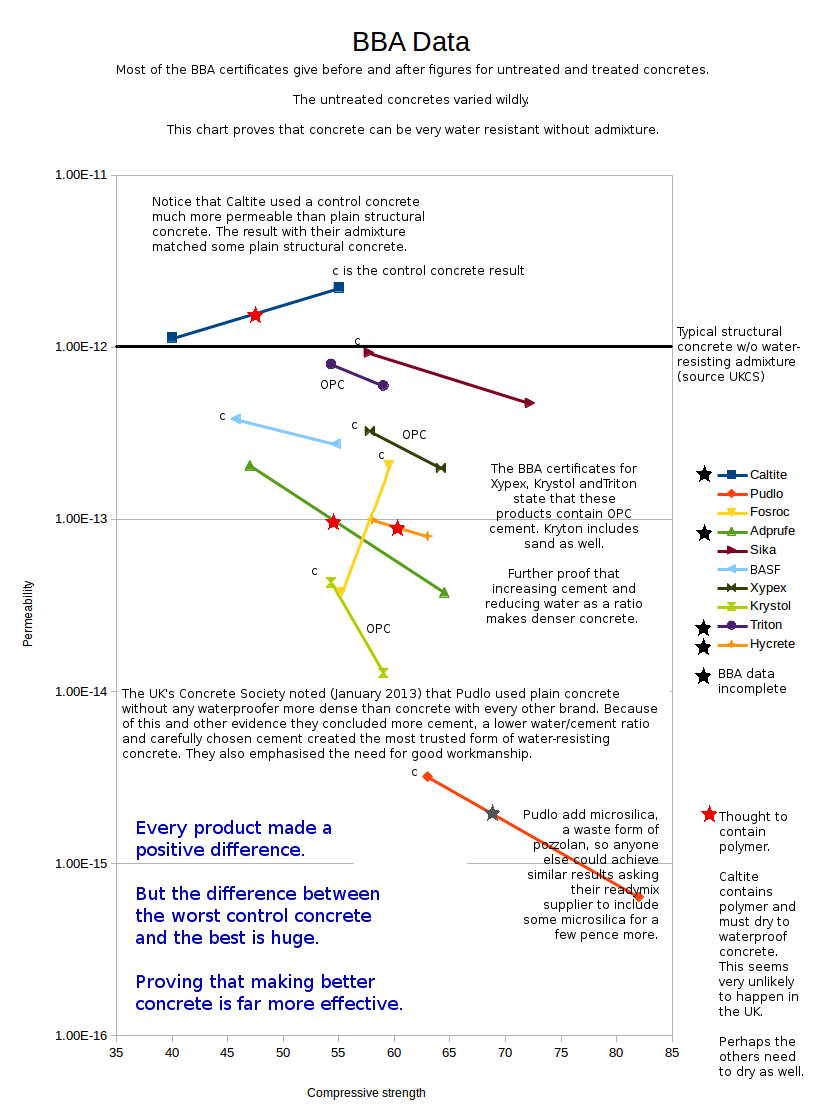

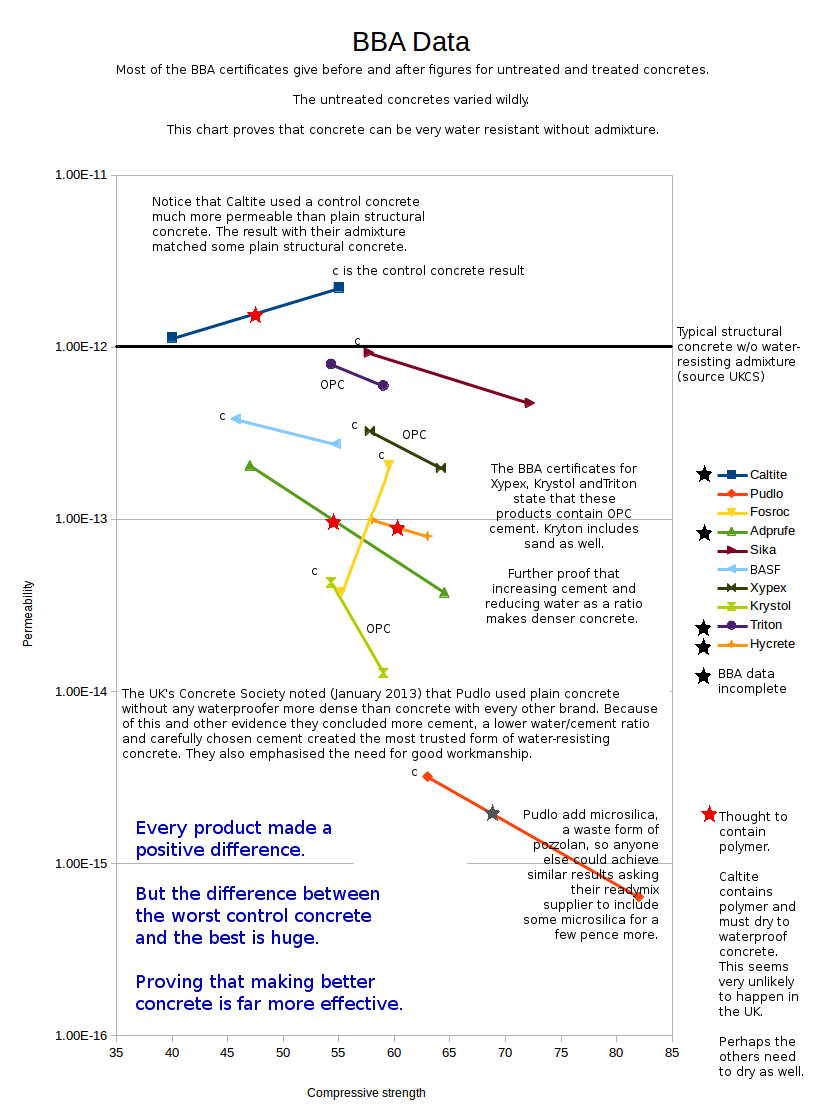

BBA certificates have figures for water permeability.

The Concrete Society had the idea of plotting them all on a chart. We have done that as well. But we have also included some best guesses. For instance, only the Caltite certificate has no figures for compressive strength.

The BBA appears to have added Caltite to a concrete that, even with the Caltite in, is still more permeable than typical structural concrete and all the other concretes they later added other admixtures to.

They added Sika admixture to concrete that even with the product in was not as resistant to permeability as the plain concretes other admixtures were added to.

The concrete Pudlo was added to outperformed all the others even before the Pudlo was added.

|

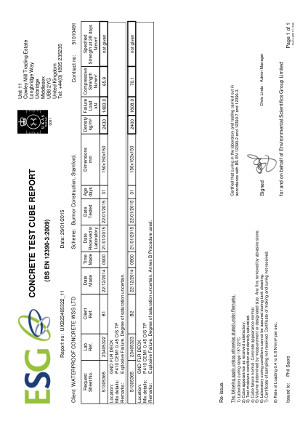

Anyone can get impressive results like Pudlo just by putting in less water. But the guys on site won't like it.

Anyone can get impressive results like Pudlo just by putting in less water. But the guys on site won't like it.

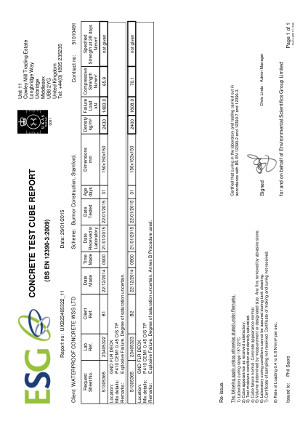

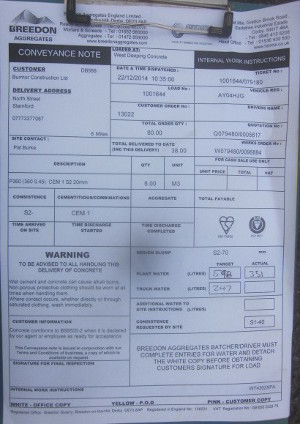

On a cold day in December 2014, I was adding my powerful plasticiser to concrete batched individually by each truck driver. The concrete was arriving dryer and dryer as the day wore on and in no time every load was suffering a flash set.

Eventually I rejected a load which is how I got to photograph the driver's copy of the ticket with the amounts of water on.

You can see for yourself, below. The driver added a total of 600 litres to 2160 kgs of cement. That is a water cement ratio of only 0.28. Even if the aggregates had been 2% water, another 216 litres, that is only a water cement ratio of 0.378.

And that meant that the gypsum in the cement had not mixed with enough water to give the concrete 2 hours of working time.

And the boys struggled.

But the test results were marvelous. Much better than they needed to be.

|

|

|

|

|

|

|

|

Compressive strength of 70.1

|

|

A zero permeability

|

|

An original delivery ticket.

|

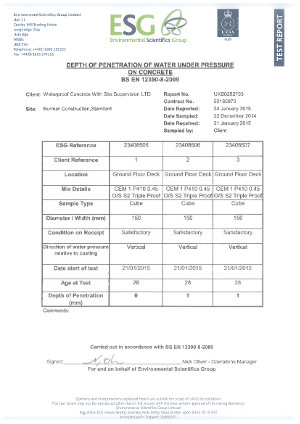

Pudlo might have some impressive figures on their test certificate, but

-

They are not impressive in the light of the 0.35 water cement ratio.

-

BBA seems to have allowed Pudlo to test concrete that no one would want to use.

Surely, that means Pudlo does not have any certification for what it sells.

|