|

|

Waterproof Concrete.

Building properly with waterproof concrete will always succeed.

The issue is 'Properly'

I have been building Properly, without a single drip getting through concrete, joints or cracks for almost a decade. 100% success.

This website explains my methods and the science in great detail.

-

Buy the readymix concrete.

-

Employ the Basement Expert to treat it when it arrives on site.

-

The Basement Expert will supervise your pour.

-

You pour it, compact it and cure it.

-

No one had any visible ingress of water since 2013.

This means no one had any leak through their workmanship or any cracks, as well as their concrete. This is the most success you would wish for. This is almost certainly more success than ANYONE else would give you. Use my waterproof concrete.

This Waterproof Concrete web site is written and maintained by Phillip Sacre, the Basement Expert.

To contact me, discuss or buy any product or service please use the link to Basement Expert in the menu column, or click here.

|

|

|

|

|

Please note. The author acknowledges all the trademarks it mentions on this site.

|

|

|

|

I am different.

My concrete is actually waterproof for exactly the same reason as everyone else's. But I don't give you the heaps of crap you get from other waterproof concrete suppliers.

My supervision is what makes the real difference. I don't allow the heaps of crap from the sub contractors either.

I waterproof the actual concrete you use on site, I supervise to prevent errors and I often got samples tested at the lab to prove you use completely waterproof concrete.

|

|

The choice is:

Do you carry on using expensive products because they have BBA certificates despite the BBA certificates proving nothing? In particular, no BBA certificate stating that the concrete is waterproof.

And, without supervision, having problems that no one else's guarantee would fix?

Or

Do you use me to waterproof your concrete, supervise and avoid all the causes of leaks?

|

|

|

My clients save a lot of money making their formwork with timber that later gets used in their building. But this is not a requirement.

|

|

I am different because I make sure the concrete is correct, I put the chemical in at site, I provide really good vibrating pokers and I supervise all the concrete going in.

My point is clear.

There isn't anyone on your side any more.

Except me.

Throughout the EU, concrete is made to BS EN 206-1 and hardened concrete is tested to BS EN 12390.

Part 3 is the test for compressive strength.

Part 8 is the test for impermeability.

Your engineer will specify C35 or C40 etc.. That is the compressive strength of the concrete and part 3 is the test to prove that your concrete is adequately strong.

To be classified impermeable, depth of penetration of water under 4 bar pressure maintained for 96 hours must average 20mm or less.

|

|

I have had many successful tests for compressive strength and water permeability under pressure to BS EN 12390 parts 3 and 8.

Click on either image below to see two original test certificates.

|

The concrete mix you will need to buy is

-

P350. This means 350kgs of cement per m³.

-

It is very important to know what cement or cement blend you will get, because this affects resistance to chemicals and shrinkage on cooling.

-

Over-sanded for pumping.

-

Target slump 60mm.

-

No other additives. Tell the readymix concrete supplier you are having a powerful plasticiser added and mixed in on site.

-

You order and pay for the concrete.

-

You pay me, the Basement Expert, for threaded rods, nuts, waterproofer, training, supervision and poker hire.

Our products and services ensure complete success. If you accept our methods and buy all we recommend you get the free leak repair guarantee.

-

You pay Basement Expert for testing to BS EN 12390 part 8 if you wish. £780 including VAT at the lab, mould hire etc..

-

Note.

In hot weather, or if the concrete needs to make a long journey, CEM 1 pure OPC can set too fast to get a good finish. OPC blended with GGBS will give you more time, though in most cases you will not need it.

Most projects do not need sulphate resistant concrete. If your does, CEM 1 with this much cement is usually resistant to DC class 2. A GGBS blend might be completely resistant to DC class 4. Check with your readymix supplier.

In 2011, the new edition of a long-respected university text stated more clearly than ever before that completely waterproof concrete could be produced without admixtures.

"concrete with a low water/cement ratio ... make the capillaries discontinuous"

Neville, A.M. (2011). Properties of Concrete. 5th ed, p330. Harlow: Pearson Education.

In 2013, the UK's Concrete Society published a report by a working group of 18 members, experts in their fields, that states:

"

water/cement ratio .... primary measure of water penetration and hence the durability of the

concrete."

The influence of integral water-resisting admixtures on the durability of concrete. P36. Concrete Society. 2013.

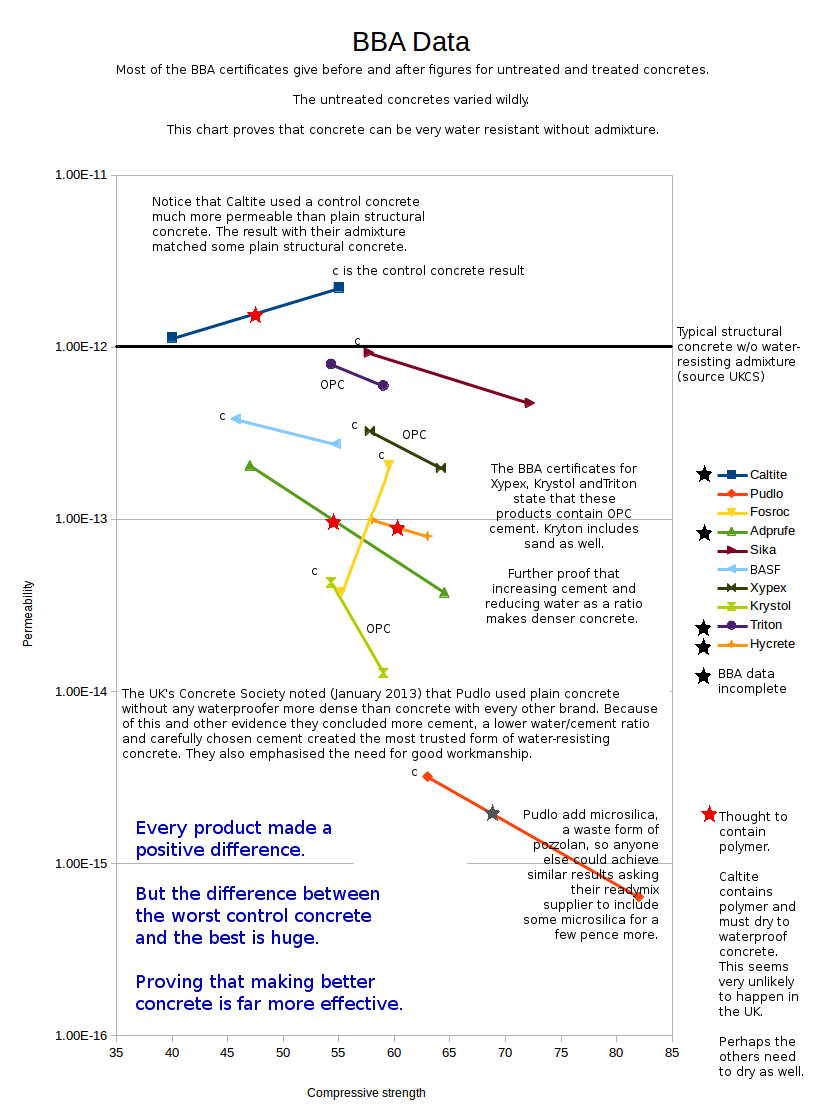

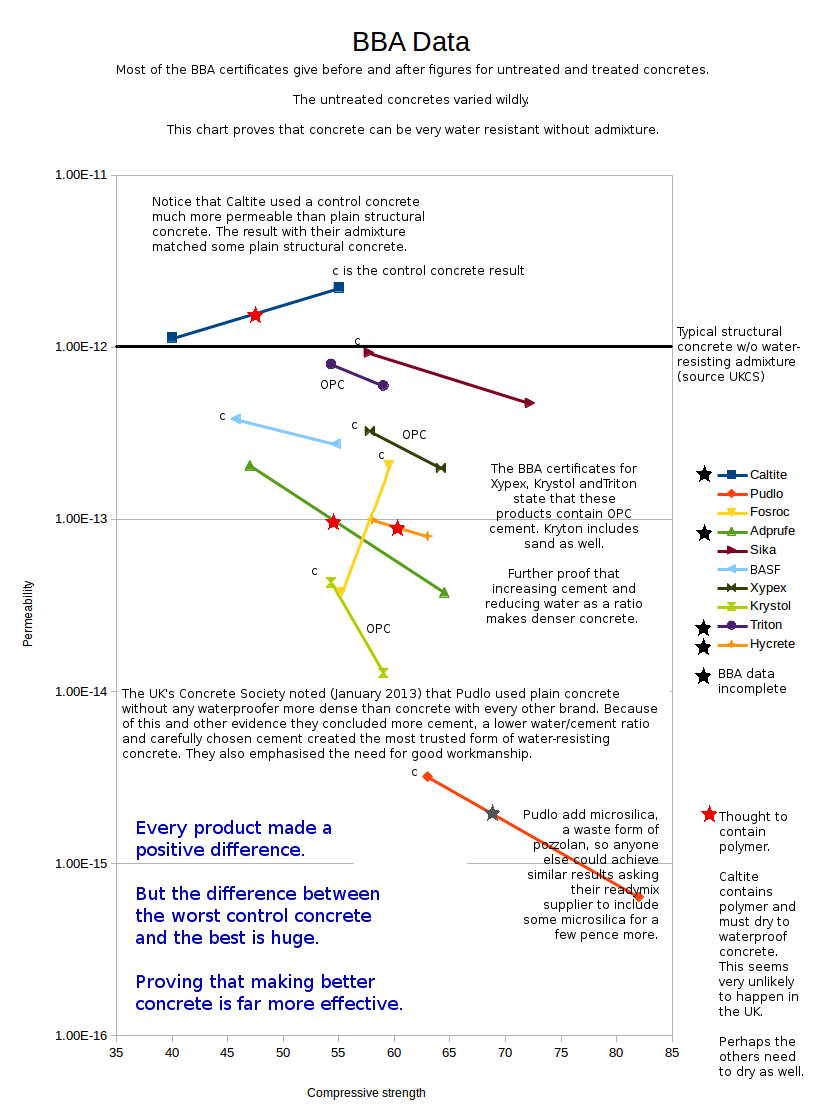

The Concrete Society had the idea to plot the various data on BBA certificates onto one chart. I have plotted the same data here, as well as a few educated guesses where marked.

|

|

Here I have plotted the before and after figures for compressive strength and water permeability from the BBA certificates I found for water-resisting admixtures for concrete.

What is striking is how varied the results for concrete without admixtures and how limited, in comparison, the benefit of a water-resisting admixture.

Some data was missing, such as Caltite compressive strength test results, so I have made up missing data with my educated guess.

This chart proves how little difference all the water-resisting products make, compared to the huge difference that a better concrete mix design can make.

The 'active' ingredient in Xypex, Krystol and Triton is only OPC. Cement. At about 100 times the usual cost.

If you click on the chart it will open in a new window so you can print it.

|

Have BBA conned you and not tested any of these concrete admixtures on site concrete?

To pump any concrete on site it needs a slump of at least 70mm. But the workforce would complain if the concrete was that stiff and add water (which would ruin any waterproofing and void any warranty) so concrete used on site needs a slump of at least 100mm.

But as this chart of data from the various BBA certificates shows, most brands seem to have cheated in the lab, proving that they did not test concrete that would be used on a building site.

These are the quoted figures on these brands' BBA certificates for the slump in the concrete with the admixture after 30 minutes, which is about how long a truck takes to batch, drive to site and manoeuvre into position.

I have also put the cement content for each and for C35A.

|

|

Pudlo

|

|

Sika

|

|

BASF

|

|

Xypex

|

|

Kryton Krystol KIM

|

|

C35A

|

|

|

|

45mm

|

|

40mm

|

|

135mm

|

|

35mm

|

|

45mm

|

|

|

|

|

|

350kgs

|

|

350kgs

|

|

350kgs

|

|

325kgs

|

|

325kgs

|

|

325kgs

|

|

Reminder. BBA testing of Caltite did not make any concrete more resistant than a plain structural concrete, neither did they quote as many figures on their certificate as the other brands shown above.

I used to buy from BASF before I went to Asia and bought the best available there. In my opinion, the slump figure for BASF - the only one tested in concrete that could be used on site - supports the science that a quality plasticiser is all that needs adding to high quality concrete to make it waterproof.

|

|

Caltite's guarantee, you will find one pictured on this web site here, guarantees that if their product fails they will put things right (but only to the value of their product).

But what does their product do? They don't say anywhere. Therefore no one could sue.

They seem to guarantee only the product but they promote 'the system'.

'The system' includes concrete with extra sand and cement and less water. So 'the system' will work because the concrete works.

Specifiers seem led to believe that the Caltite rep on site supervises.

But on site the rep makes the foreman sign a disclaimer saying the Caltite representative was not there to supervise and Caltite is not responsible for workmanship.

I have further information from Sika and Kryton as well. They aren't any better. Indeed the worst horror stories I heard over the years all involved Sika.

|

|

Most specifiers think that the only way to get anything close to supervision is to buy a BBA certified water-resisting admixture.

But you shouldn't be fooled that you will get supervision, or by the bogus guarantees that come as well, just because a product has a BBA certificate.

|

We supply supervision and vibrating pokers that really work well. That way you know Supervision and good compaction will happen.

Please go the Basement Expert web site for details of the threaded fibreglass rods and nuts.

disclaimer and copyright

|

|